How Does Blowmoulding machine Work?

Blowmoulding forming includes the handling of plastic pellets through a warmed screw and barrel to warm the plastic to a liquid state. The screw and barrel is like a drill course of action where the material is pushed forward while the screw is turning.

The liquid material ways out through the finish of the screw and barrel by means of a diehead, which shapes the plastic into a round and hollow cylinder shape, which is known as a parison.

When the parison is adequately long, a shape with two separate parts is moved into position and shut around the parison. A blade at that point cuts the parison, and the form is moved far removed, to permit the parison to keep expelling for the following machine cycle.

A blowpin then enters the neck or opening in the form, a blows the parison to the state of the shape with packed air, and the plastic is permitted to cool against the shape surface. While the plastic item is framed and permitted to cool, the following parison is prepared through the screw and barrel, prepared for the following cycle to begin.The device at that point opens, and discharges the completed the process of embellishment.

The complete process duration taken to fabricate a plastic item from blowmoulding will rely upon a few unique factors, for example, divider thickness of the plastic, and generally size of the part being shaped.

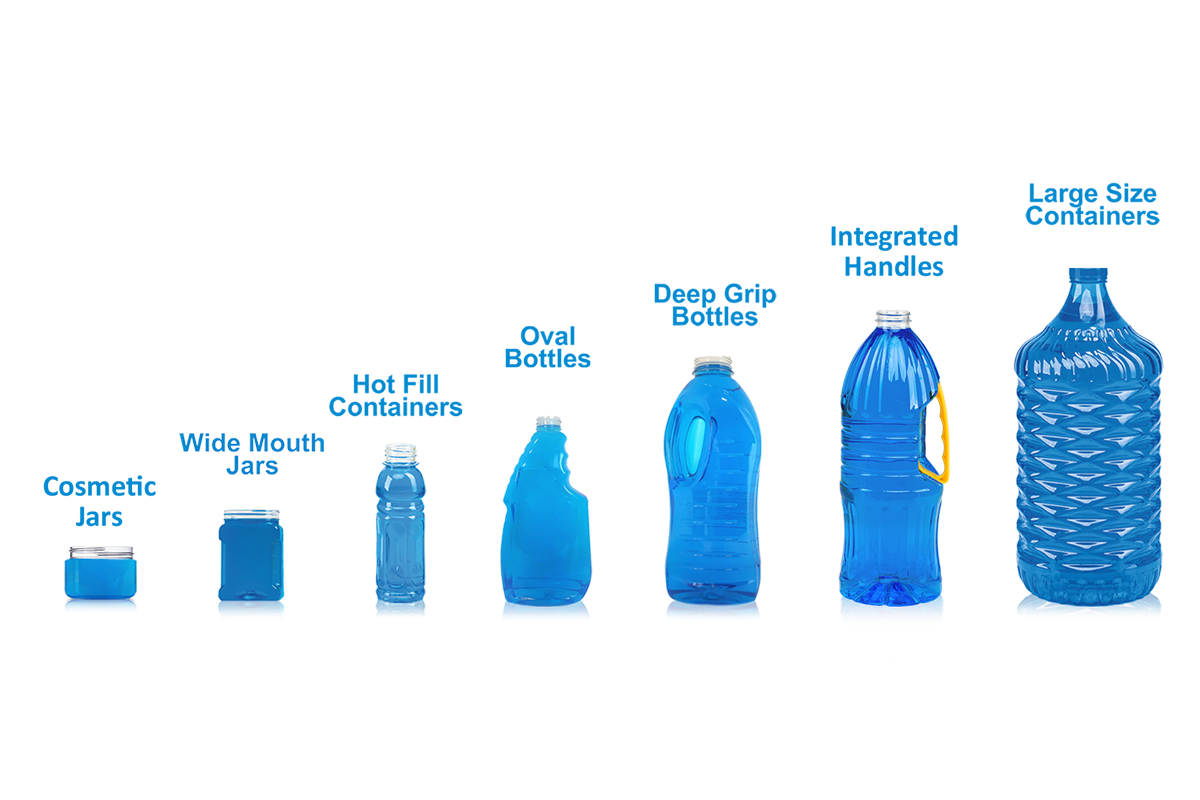

Things that are created from blowmoulding can fluctuate in size from little restorative holders up to huge drums and tanks, and formed parts range from buyer products, food and refreshment stockpiling, car, and mechanical employments.

Source of URL: - https://sites.google.com/view/cruairgas0/home

For more info: - pet blowmoulding machines online

Comments

Post a Comment